Halloween Flyer 1

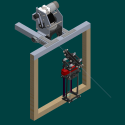

My favorite holiday is easily Halloween and have always liked more of a traditional aesthetic. Never been a fan of the blow-up decorations or animatronic zombie type child terrifiers. Back in 2020, I wanted to be able to deliver candy to trick or treaters in a way that prevented the candy cauldron becoming the covid cauldron and thought, hey, this seems like a job for an automated system.Most automated machines are not what I would consider friendly to the Halloween aesthetic, so my brother and I came up with the idea of a “flying” ghost or bat on a zip line. Pretty soon into the conceptual design phase, we settled on the ghost due to the simpler form. This concept became “Halloween Flyer 1” (HWF-1).

I started on HWF 1 in early October, so was pretty rushed to get it to completion. The system comprised of a “Flyer” that rolled down a set of parallel fishing lines, and had another reel attached to a 550 brushed motor for the return. Here’s a video of the system working when I put it back together in July 2021:

HWF-1 Demo Video

Position Control:

The position of the flyer along the two guide lines was controlled by a 550 motor from a printer running off a 24V 4A power brick. Originally I was thinking hey, this could be a fully autonomous system and I’ll run the motor off a an ESC and work on a closed loop control system for retraction and some current feedba– then I decided to use a drill trigger and opt for manual due to the 3 week build window.

A similar reduction of scope happened with the retraction spool, I originally wanted to make a custom spool with a clutch that would engage and disengage using a solenoid. The clutch I came up with was pretty neat, but had way higher friction and worse line wrap characteristics compared to the COTS option: a fishing reel. I was already using for the guide lines, so why not add another. The final drive system for the reel was a 4ish-1 reduction using pulleys and a belt, again from some inkjet printers.

In the end the manual position control system worked really well. I was surprised at how well the 1mm pitch belt preformed under the load conditions which included stalling the motor and pretty rapid direction changes during operator training. The “flying” part of the flyer was easily the speed of retraction. After a bit of practice, my brother and I could get an average retraction speed of about 4m/s (or around 9mph).

The position control module was mounted to a scrap wood frame that kept the window. In the first attempt, the guide line sag was so high that the flyer couldn’t be pulled back though the window, making reloading a pain. Two hooks were added to pick up the slack which worked just fine. Over the course of testing & Halloween operation, the guide lines stretched by at least 300mm, so periodic tensioning was required.

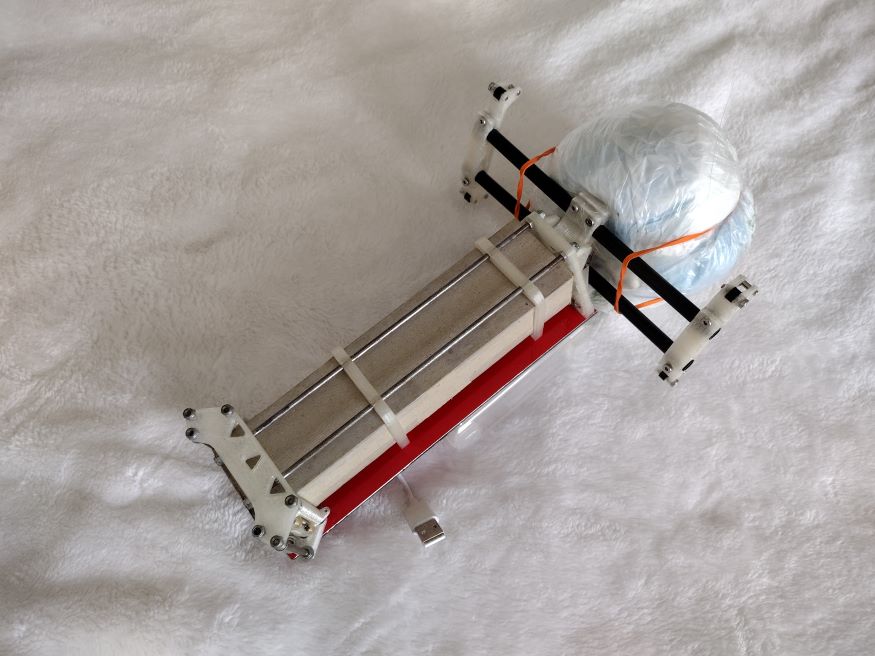

Flyer:

The main structure of the flyer is a strip of red Euroboard also known as an aluminum-hdpe sandwich. The main tube that “nerds” candy was loaded into was made from non-corrugated cardboard due to the good strength to weight ratio and that I could get it for free. The main tube was supported by some 3mm rods and PLA printed ribs. Most of the hangar assembly was also made of PLA brackets and 2 ABS tubes. The guide line rollers were originally nylon rollers, but they got pretty cut up during testing and I ended up just letting the lines ride on stainless steel pins.The coolest part of the flyer mechanically was the loading and dropping mechanism. Candy boxes were held in the tube by a set of “fingers” actuated by an MG90 servo. The fingers had a set of prongs on them that were spring loaded inward (red lines indicate small elastic bands), acting as a 1 way door. This is so that candy could be loaded (pink arrow) without the rest falling out. Once the servo rotated the fingers (green arrow), all the candy would be dropped. This mechanism worked well on the first revision and made loading much easier.

Here you can see the yellowish elastic bands in the lower part of the image.

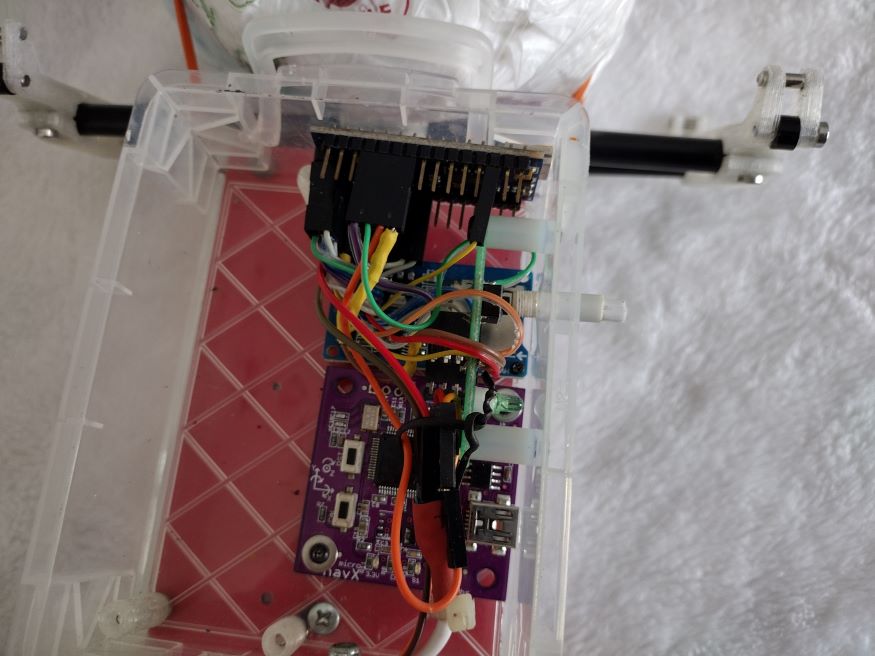

With the goal of achieving semi- autonomous dropping, the flyer had an NavXmini on it for position tracking. The idea was that it would detect when the retraction motor yanked on the return line and stopped the flyer from descending. The NavX is mega overkill for this task and for someone who had pretty much no experience with merging I^2 registers, I spent most of the 3 days before Oct. 31 struggling to get any data out of the sensor. In the hour before trick or treat I ended up just setting a 30 second delay once the “start” button was pressed before the drop servo would release the goods. I made the joke that the scary part of this Halloween decoration was the fact it had a 9axis IMU on it and still just ran on a timer 💀. The rest of the electronics were pretty straightforward. An Arduino nano with a button panel for staring the dropping sequence, an SD card reader for collecting test data. For power, I used a 2000mAh 5V USB Li-ion battery pack which lasted the whole night on Halloween.

Here's there electroncis housing. I used a part of a mechancal pencil to push the "start" button without needing to place the button board outside the container.

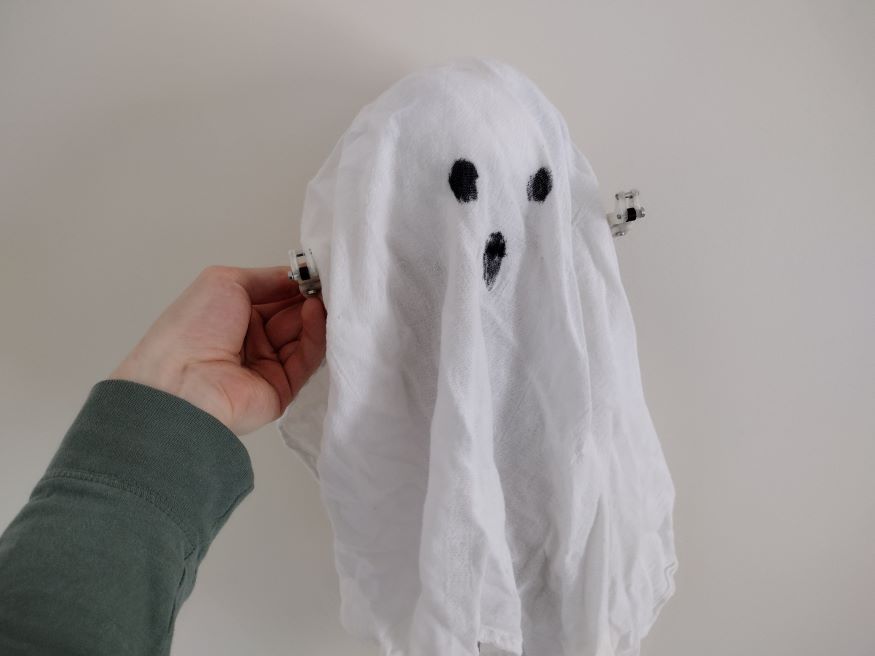

Costume:

My brother suggested the ghost costume idea, and we executed it by balling up a bunch of old plastic bags and rubber banding them to the top of the flyer as a “head” so the ghost would indeed be ghost shaped. The sheet is just an old dish towel with sharpied on eyes. The coolest part of the costume was a sound box pulled from a yellow foam-bag (looks like a bean bag but made of foam?) toy that laughs when you squeeze it? Before each delivery run we’d just hit the soundbox before releasing the flyer, and the laughing lasted a good 20 seconds.

Plasic bag ball to provide more of a ghost shape.

Soundbox doner.

Full costume.

Results:

For all the compromises made, the not-so automated system worked well. We delivered about 1.5lbs of nerds candy over the night and ran more than 20 cycles. Battery didn’t run down, and the retraction system worked as well as it could have. The goal for the future was to refit this system to enable fully autonomous operation, but there are some fundamental issues with HWF-1.Issues and areas for improvement:

Line Stretch:

Having to keep re-tensioning the guide lines was not great, and they got iced-over after leaving the assembly up on Nov. 1. When I put this system back together in 90deg July heat, the lines were much weaker than back in October and they snapped a few times while tensioning. It turns out nylon lines don’t like to be frozen/thawed and later exposed to significant heat?Feedback from flyer to position control module:

To make the system fully autonomous, the flyer need to talk to the position control module to let it know then to stop the descent and ascent. Two easy solutions seem to exist here: put the drive system on the flyer, or use wireless communication between the two. HWF-2 explored the first option, and HWF-3 is currently exploring the second.Different payload types:

HWF-1 could only really drop nerds candy which is pretty limiting. Future iterations look at a shape agnostic loader/dropper.Weight optimization:

Euroboard is heavy and I didn’t make much of an effort to reduce weight on HWF-1. In some ways weight is good because it makes the descent faster, but also puts more load on the retraction system. Speaking of which, the retraction drive worked well, but it too could be optimized in the future and an encoder could be added for closed loop control.